Manufacturing

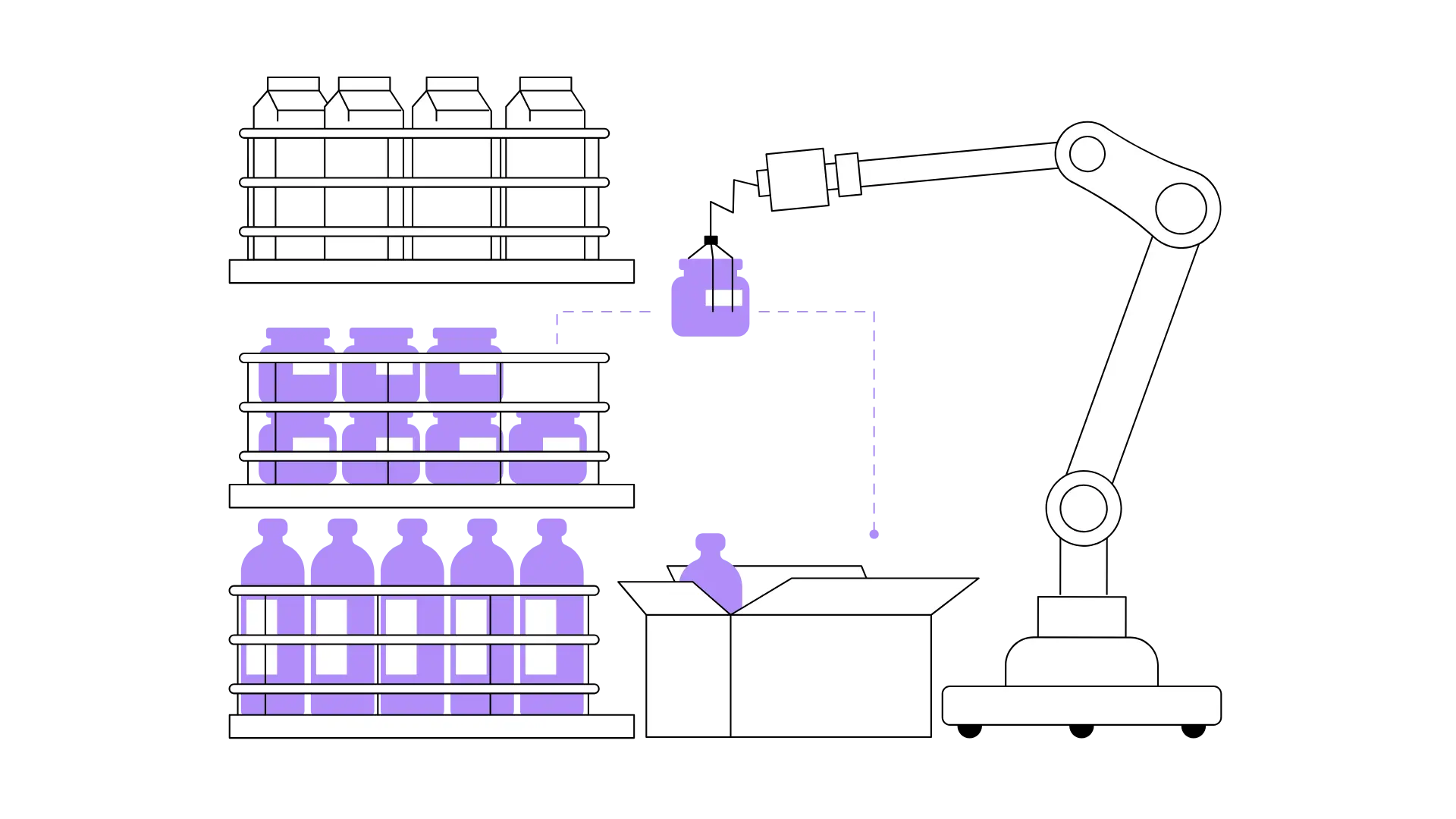

Tunity Warehouse Solutions:

"TAP INTO THE POWER OF THE SMART WAREHOUSE."

Having an integrated supply chain allows you to increase productivity throughout your warehouse— from receiving to picking to cross-docking and shipping. Whether your warehouse is for storage of raw materials and manufactured goods, cold storage, distribution, fulfillment or long- or short-term dock storage, Tunity solutions help you increase accuracy, boost efficiency, exceed operational expectations and achieve the agility to stay competitive and connected to your inventory at all times.

Our Process in Six Easy Steps

1. Receiving Your Product

Move materials from dock to stock with real-time, accurate data capture. Label cartons and reconcile inventory using our RFID software.

2. Put-Away & Replenishment

Streamline downstream processes such as picking, cycle counting, and reordering through accurate and efficient put-away operations.

3. Fast & Accurate Picking

Achieve both speed and accuracy—whether you're picking by pallet, case, or handling high-velocity orders.

4. Inventory & Materials

Quickly get accurate counts and precise locations of all raw materials and finished goods through essential cycle counts.

5. Packing & Staging

Ensure order accuracy, enable full traceability, and dynamically stage shipments for error-free outbound loading.

6. Returns Management

Add visibility to your returns process and streamline your workflows. Our solution helps you quickly restock, refurbish or discontinue goods to control waste.

500+ RFID Projects Completed

Contact us for a personalized meeting

Trusted By: